Products

Machine decals and safety decals play a vital role in various industries, adding functionality, safety, and branding to an array of equipment. From construction and manufacturing to automotive and agriculture, these decals are more than simple stickers. It is important to know the best materials and how you can order decals that are strong and durable for your safety and the safety of your staff.

Machine decals fall into several categories, each serving a unique function. Find out which type of machine decal would be right for you:

Machine decals fall into several categories, each serving a unique function. Find out which type of machine decal would be right for you:

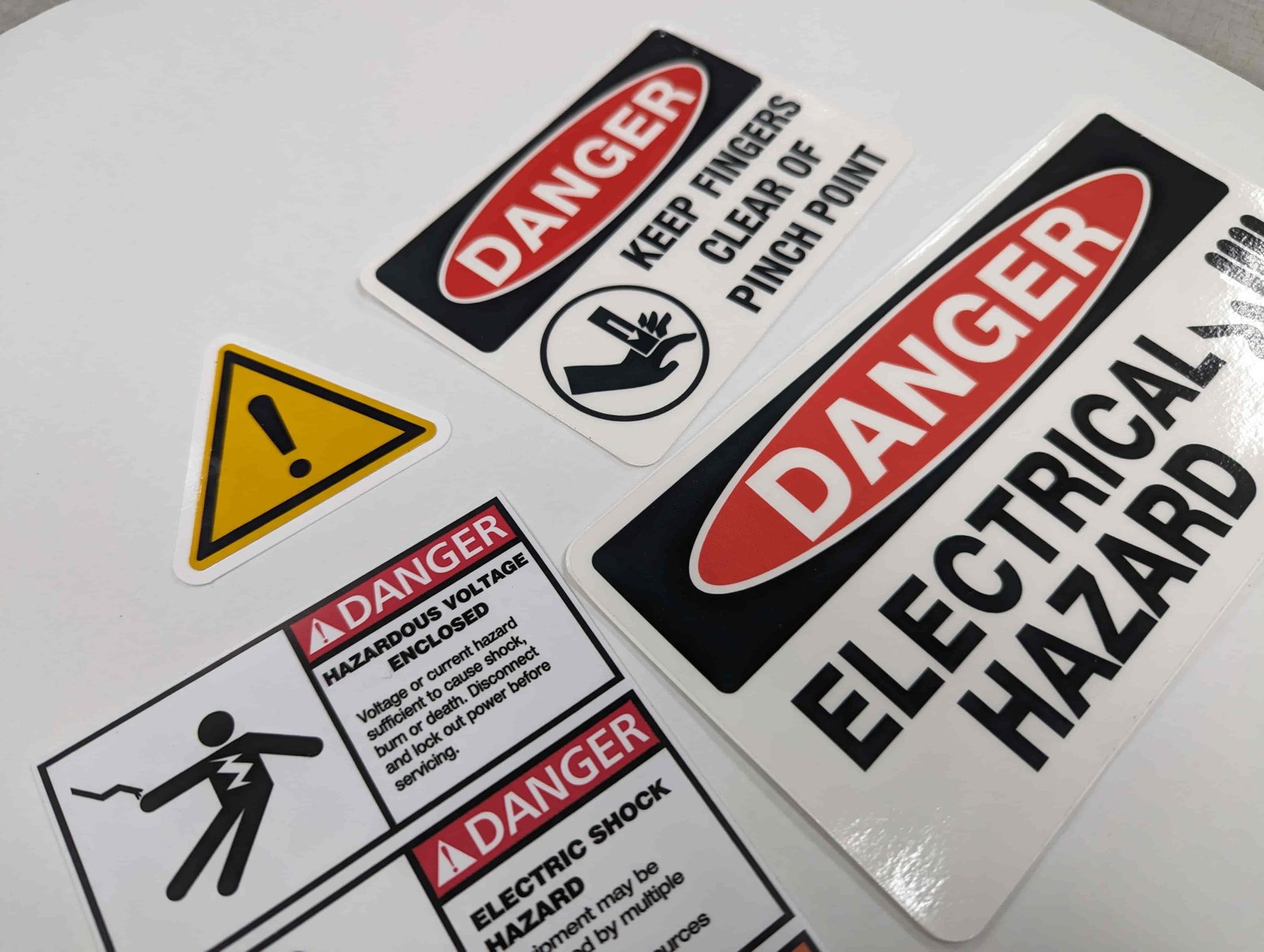

Safety and Instructional Decals: Safety decals are essential in industries where machinery poses significant hazards. They provide warnings about specific dangers—like pinch points, high voltage, or toxic substances—and often use bright colors and universal symbols for quick recognition. Instructional decals are used to display operating guidelines or emergency procedures. Both safety and instructional decals help companies comply with regulatory standards, such as OSHA or ANSI in the U.S., and can reduce the risk of accidents.

Maintenance and Inspection Decals: These decals help operators and maintenance teams keep track of when a machine was last serviced or inspected. They might include checklists, spaces for dates, or other details that ensure machinery remains in peak operating condition. These decals are particularly useful in settings where maintenance logs are crucial, such as in aviation, heavy machinery, and manufacturing industries.

Identification Decals: Machine identification decals typically include serial numbers, model numbers, and asset tracking codes like QR codes. They make it easy to identify and inventory machines, which is particularly valuable for companies with large fleets of similar equipment.

Branding Decals: These decals display logos, names, and often slogans or website links to help a company establish a recognizable image. They’re typically large, strategically placed for visibility, and often feature the colors and fonts associated with a brand. Branding decals are commonly seen on construction vehicles, company-owned trucks, and factory machinery, helping to boost brand visibility and recognition.

Maintenance and Inspection Decals: These decals help operators and maintenance teams keep track of when a machine was last serviced or inspected. They might include checklists, spaces for dates, or other details that ensure machinery remains in peak operating condition. These decals are particularly useful in settings where maintenance logs are crucial, such as in aviation, heavy machinery, and manufacturing industries.

Identification Decals: Machine identification decals typically include serial numbers, model numbers, and asset tracking codes like QR codes. They make it easy to identify and inventory machines, which is particularly valuable for companies with large fleets of similar equipment.

Branding Decals: These decals display logos, names, and often slogans or website links to help a company establish a recognizable image. They’re typically large, strategically placed for visibility, and often feature the colors and fonts associated with a brand. Branding decals are commonly seen on construction vehicles, company-owned trucks, and factory machinery, helping to boost brand visibility and recognition.

Our Safety Decals Can be Found Here:

The Importance of Choosing Compliant Safety Decals

Decal Material and Durabiltiy

Machine decals are manufactured to withstand the demanding environments in which many machines operate. They are usually made from vinyl, which is waterproof and UV-resistant, ensuring lasting quality without fading, peeling, or cracking. For high-traffic or hazardous locations, laminated decals provide added protection against chemicals, abrasion, and weather exposure. High-quality adhesives ensure decals remain secure without damaging the machine’s paint or surface when removed.

Decal Application Process

To apply a machine decal, the surface must be cleaned and dried thoroughly before application, and a squeegee or similar tool is often used to apply even pressure, preventing bubbles and ensuring a smooth finish. For complex or irregular surfaces, heat guns or specialized tools may be used to mold the decal for a perfect fit. High-quality vinyl decals typically have an easy-to-remove backing, making them easier to apply quickly and accurately.

Email us Today to Start an OrderSafety DecalsRemoval and Replacement

Decals on machinery occasionally need to be removed, either for updating information or replacing damaged decals. Proper removal techniques involve applying heat or using solvent-based adhesive removers to prevent residue and protect the machine’s paint. Once removed, decals are often replaced to ensure the machine continues to convey clear and accurate information.

Custom decals and labels since 1988

Call now |

Finishing Options