Products

Why should I know the difference between cast and calendered vinyl?

To a lot of people, a decal is just that: a decal. They just need something sticky with their logo on it to put on the companies truck. That's just fine, and we can easily provide that for them. However, you want a decal that is designed specifically for YOUR business. We understand the intricacies that are involved in every business decision, and deciding the specifications of your decal is no different.

Each business uses their decals, graphics, labels, and stickers differently. Some are put outside, some inside, in warm weather and in cold. Some decals go on flat surfaces, some go on spheres. All of these factors and more in various combinations have an associated vinyl that works best in that scenario.

Each business uses their decals, graphics, labels, and stickers differently. Some are put outside, some inside, in warm weather and in cold. Some decals go on flat surfaces, some go on spheres. All of these factors and more in various combinations have an associated vinyl that works best in that scenario.

Cast vs Calendered Vinyl

Calendered Vinyl

Calendered vinyl gets in name from the process from which is it manufactured: Calendering. The process of calendaring is very similar to making pie, or pizza dough. Many different materials can be calendered, and each process involves basically the same concept: Taking material heated until its somewhere between and liquid and a solid. Then, the material is poured onto a conveyor belt and passed through a set of rollers, which stretches, presses, and cools the material into a rigid sheet.

Cast Vinyl

Cast vinyl is the industry standard for vinyl graphics, decals, labels, and stickers. Cast vinyl begins as a heated liquid solution, of PVC and other solvents that give the vinyl different levels and kinds of gloss. Then poured into what looks like (and could be) a giant baking sheet. This sheet travels under several ovens, which evaporate the solvents from the mixture, leaving behind a thin vinyl film. The material is then wound onto large rolls, then applied with adhesive.

Calendered vinyl is thicker, heavier, less conformable, and has more dimensional stability. Decals printed on calendered vinyl are much easier to handle and apply than cast vinyl. This makes calendered vinyl decals perfect for flat or curved surfaces.

Calendered vinyl decals are durable in the sense that they are scratch and bend resistant. Their memory makes them very hard to permanently crease or bend, and their rigid surface makes scratches and physical wear less of an issue.

Another benefit of calendering vinyl is that it is more cost effective than other vinyl manufacturing processes. The calendaring process takes less material, energy, and labor to produce. These savings are reflected however, in the lifespan of the decal.

Calendered vinyl is sometimes referred to as "temporary" or "short-term" decals. Calendered vinyl has "memory" of its' old life as a heated, malleable liquid. This means that throughout its' lifetime, it will attempt to return to its' original form, which unfortunately, is not the nice flat form it is as a decal. The lifespan of a calendered vinyl graphic is anywhere between 1-5 years, depending on the quality of the vinyl.

Calendered vinyl decals are durable in the sense that they are scratch and bend resistant. Their memory makes them very hard to permanently crease or bend, and their rigid surface makes scratches and physical wear less of an issue.

Another benefit of calendering vinyl is that it is more cost effective than other vinyl manufacturing processes. The calendaring process takes less material, energy, and labor to produce. These savings are reflected however, in the lifespan of the decal.

Calendered vinyl is sometimes referred to as "temporary" or "short-term" decals. Calendered vinyl has "memory" of its' old life as a heated, malleable liquid. This means that throughout its' lifetime, it will attempt to return to its' original form, which unfortunately, is not the nice flat form it is as a decal. The lifespan of a calendered vinyl graphic is anywhere between 1-5 years, depending on the quality of the vinyl.

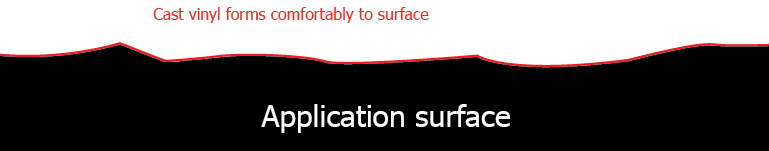

The process of casting vinyl has many benefits, and is considered an industry standard for most decal projects. Cast vinyl is thinner, lighter, and more flexible than calendered vinyl. This makes cast vinyl perfect for curved or irregular surfaces.

Cast vinyl decals also have a much longer lifespan than calendered vinyl. This is because cast vinyl has no original form it wants to return to. It will not attempt to become flat again. Calendered vinyl decals have a short lifespan of 1-5 years, but cast vinyl can last up to 9 years outdoors.

Cast vinyl decals also have a much longer lifespan than calendered vinyl. This is because cast vinyl has no original form it wants to return to. It will not attempt to become flat again. Calendered vinyl decals have a short lifespan of 1-5 years, but cast vinyl can last up to 9 years outdoors.

Custom decals and labels since 1988

Call now |

Finishing Options